Steel panel dent repair is a complex process requiring skilled technicians who employ advanced techniques to restore vehicle bodywork to its original condition, preserving both structural integrity and aesthetic appeal. This involves not just visible dents but also hidden issues like corrosion, rust, and misaligned panels that can significantly impact the car's performance. Professionals use specialized tools for thorough inspection and precise repair methods such as frame straightening or paintless dent repair. Combining dent repair with auto painting services ensures both visual and structural perfection. Effective steel panel dent repair demands meticulous attention to detail, quality control measures, and regular maintenance checks to prevent hidden damage.

In the realm of construction and automotive maintenance, proper steel panel dent repair is paramount. While the visible restoration of dents may seem straightforward, underlying damage often goes unnoticed. This article delves into the intricacies of steel panel dent repair processes, revealing common hidden damages that can compromise structural integrity. We provide strategies for effective detection and prevention, ensuring long-lasting repairs without unseen risks.

- Understanding Steel Panel Dent Repair Processes

- Unveiling Common Hidden Damages

- Strategies for Effective Detection and Prevention

Understanding Steel Panel Dent Repair Processes

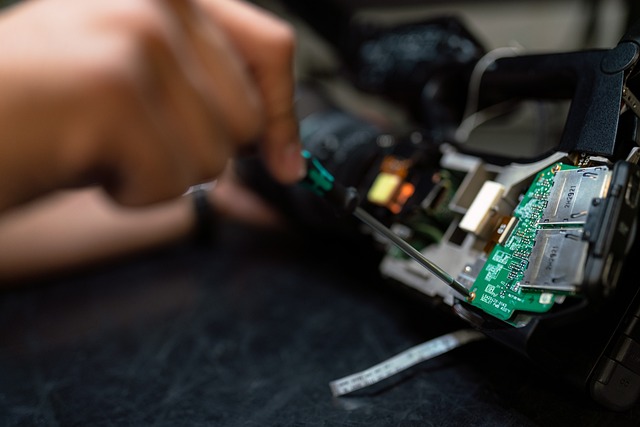

The process of steel panel dent repair is a meticulous art that requires a deep understanding of metal mechanics and advanced techniques. It’s not merely about fixing the visible dents; it involves careful assessment, precise manipulation, and often, specialized tools to restore the panel to its original condition. Professionals in this field use methods like frame straightening, where panels are adjusted back into place, or more innovative approaches such as paintless dent repair, which preserves the factory finish without the need for repainting.

Every steel panel dent repair job begins with a thorough inspection to identify the extent of the damage, be it from minor bumps and scratches to severe deformities. Technicians then employ various strategies tailored to the vehicle’s make and model, ensuring that not only does the car look as good as new but also maintains its structural integrity. This meticulous attention to detail is what sets apart a quality auto body repair job from mere surface fixes.

Unveiling Common Hidden Damages

In the course of steel panel dent repair jobs, it’s crucial to unveil common hidden damages that often go unnoticed. Beyond the visible dents, deeper issues like corrosion, rust buildup, and misaligned panels can lurk beneath the surface. These hidden damages not only compromise the structural integrity of the panels but also impact the overall quality of the repair. Thorough inspection and advanced techniques, such as those employed in professional auto detailing, are essential to detect these problems early on.

By combining expertise in steel panel dent repair with complementary services like auto painting and tire services, technicians can provide comprehensive solutions. They can ensure not just a visually appealing fix but also address underlying structural concerns. This holistic approach guarantees that the repaired surface not only looks good but is also as robust and reliable as new, safeguarding against future damage and ensuring optimal performance in various environmental conditions.

Strategies for Effective Detection and Prevention

Effective detection and prevention of hidden damage during steel panel dent repairs are crucial to ensuring the integrity of vehicle bodywork. The first step involves meticulous inspection using specialized tools designed to reveal even the subtlest imperfections. This includes utilizing high-resolution cameras, UV lights, and digital measurement devices that can expose pinholes, cracks, or corrosion not visible to the naked eye. These techniques, commonly employed in professional vehicle repair shops, help identify areas that may have been missed during initial assessment.

Prevention strategies should focus on establishing robust quality control measures. This entails proper training for technicians on advanced dent removal techniques and emphasizing meticulous attention to detail. Using high-quality repair tools and materials compatible with steel panel construction also reduces the risk of hidden damage. Regular maintenance checks, especially in regions with harsh climates, can further mitigate potential issues by identifying and addressing corrosion before it becomes a significant problem in vehicle body repair.

In conclusion, while steel panel dent repair is a common practice, it’s crucial to be aware of potential hidden damages that can go unnoticed. By understanding the repair processes and implementing effective detection strategies, professionals can prevent these hidden issues, ensuring lasting and quality results in every steel panel restoration project.